The Key to Good Floors: Subflooring

If you want beautiful and quiet floors, get to know your subfloors. For pier and beam foundations, whether in your new garden shed or in your home, no one wants a squeaky or sagging floor. If you’re building a new floor or renovating what you have, understanding what is beneath your feet is the key to getting squeak-free comfort for years to come.

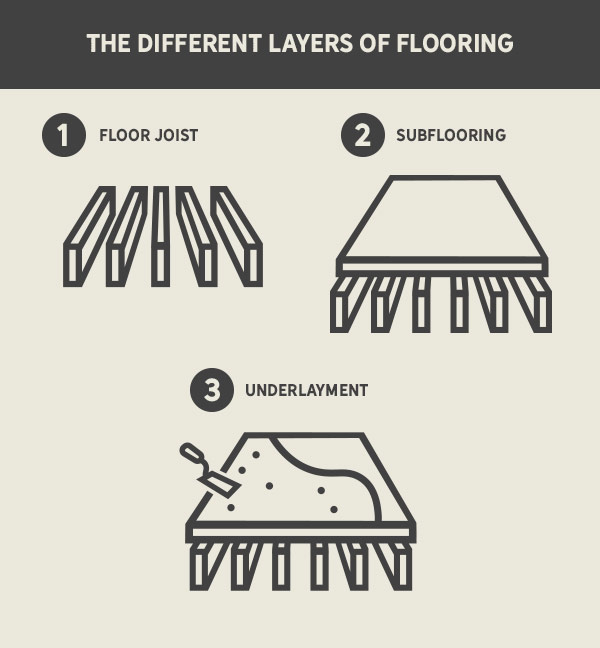

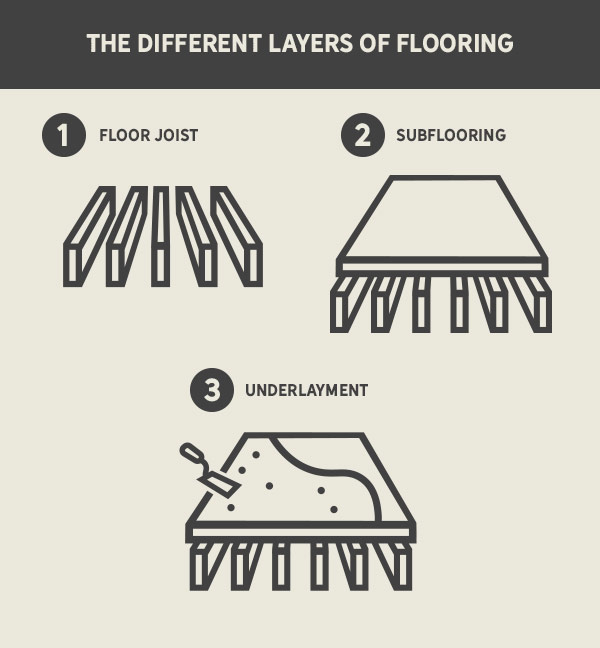

Flooring Layers

Your floors, whether in your home or in a new outdoor shed, include four main parts. These are joists, subfloor, underlayment, and finished flooring. You are already familiar with finished flooring as this is the hardwood, laminate, carpet, or tiles you walk on every day. Let’s explore what is beneath that you can’t see:

- Floor joists are the very bottom beams that are a part of the initial framing of a build and are arranged parallel to each other. They are commonly I-joists, dimensional lumber, or trusses. I-joists and trusses are preferred as they are more stable and less squeak-prone.

- Subflooring is the next layer. Subfloor panels installed on top of the joists provide the structure and support for the rest of your flooring. If you have a concrete slab, that is your subfloor without the need for joists. If you are building a shed, your flooring levels may stop here depending on your construction plans and if you want finished flooring.

- Underlayment is just before your finished floor to provide a level surface. This layer is sometimes not used depending on what will be placed on top. Underlayment can help your finished floor be adhered to the subfloor.

Subflooring Materials

There are two main types of materials used for subfloor: plywood and OSB. There is some debate among the building community about which material is superior, but they are both very popular options. Each has its advantages and disadvantages as plywood and OSB can be subject to edge swell during a rainstorm and OSB tends to cause squeaks more so than plywood.

Both plywood and OSB subflooring have two end types: smooth and tongue-and-groove. Smooth ends are just as they sound with a flat, straight edge, while tongue-and-groove edges interlock like puzzle pieces. This type is preferred for subflooring as it tends to not move as much as the smooth-edged variety and thus minimizes squeaky floors.

Another type of subfloor is concrete, which is typical for basements. Concrete can be used with tile and stone finished flooring, but a moisture barrier will need to be placed as an underlayment if being used with any type of wood.

If you are renovating an older space, you might see simple wood planks for subflooring that used to be the standard.

Installation

Proper installation is important as subflooring is very difficult to remove and fix if something goes wrong. Plywood or OSB subfloor panels are laid crosswise over the joists and the seems are staggered for added strength. The boards are glued to the joists to provide staying power. Special brand adhesives are commonly used, or even a caulk-type of adhesive. These are used like a caulk sealant with a caulk gun to run a bead of the adhesive down the joist. After being glued, the boards are nailed or screwed down. Careful placement is necessary as too little spacing could interfere with the natural expansion of the board over time and cause damage. Of course, too much space will cause noise as movement happens. This is where most squeaks will start to be noticeable as you walk along your floor. Between each subfloor panel, there should be a 1/8-inch gap.

With a concrete subfloor, OSB can be “floated” by using an adhesive to glue the OSB to the concrete.

When adding subflooring, it is important to look at:

- Loads that the subfloor will need to be able to withstand will help determine the integrity of your floor for years to come. Loads like refrigerators being moved around or even the type of tile you pick should all be considered.

- Fastener holding power is how well fasteners stay in the subfloor. Loose fasteners can cause movement and squeaks. The best fasteners are screws that have crevices along the shank to grip the wood firmly. Where the fasteners are placed is also important as this will keep the board in place and reduce movement and bounce under your feet. Some manufacturers print guides directly on the panels so you can space your fasteners consistently and easily to comply with building regulations.

- Exposure to moisture on the jobsite as rainfall or other wet weather during the construction process can cause the wood to swell. If your subfloors are exposed to wet weather, it is important to get them dry as soon as possible. Wetvacs work great for this job. Even so, you’ll probably need to spend extra time sanding the swelled edge before it can be used to create a level surface.

- Bond performance is based on how well the subfloor glue or adhesive bonds the subflooring panels to the joists. Just like the fasteners need to grip the board well, the glue needs to be strong enough to prevent lose boards that cause squeaks. This adhesive should be able to withstand wet weather and other types of outdoor exposure during the building process and afterwards.

McCoy's Carries What You Need

Along with plywood and OSB, McCoy’s carries AdvanTech subflooring which is a high-density OSB that gives strength for a longer lasting subfloor. Their moisture-resistant resin technology is designed to reduce edge swell and their fastener-holding power reduces squeaks for a quiet floor. Whatever subfloor you choose, McCoy’s has all the building materials you need for your next project, big or small. Shop in-store or online today.