Medium Density Fiberboard: How Can MDF Work for You?

Did you know that medium-density fiberboard (MDF) could be an option for your next project? As an engineered wood product, it's frequently used in modern construction, in furniture making, and in other applications. It’s a great option for many DIY projects because it’s versatile, strong, and comes with a host of other benefits as well. Here’s how you can use MDF in your next project.

What is MDF?

This type of board is made of sawdust and shavings (common milling byproducts) that are dried and mixed with resins and wax. The mixture is then pressed into flat panels via extreme pressure and high temperatures. MDF has no knots or grain and resists warping because it's engineered densely. Unlike plywood, which is made from gluing thin sheets of veneer together in alternating patterns to create strength, MDF is very strong but also heavy due to the volume of materials used in its construction.

Commonly sold in sheets, you can typically find it in tan or dark brown colors in sheets either 1/2-inch or 3/4-inch thick (though different thicknesses include 5.5mm and 5/8-inch thick boards at McCoy’s). Sheets typically come in a standard size of 49 x 97 inches and an ultra-light option. MDF can also be sold as pre-cut decorative moulding pieces, cabinet doors, and other project materials.

How Do You Use MDF?

MDF is ideal for indoor projects that need specific shaping, cutting, and drilling. It has a smooth surface that resists splintering and can be painted easily. It’s similar to working with real wood but can be more budget-friendly for your project.

It can be used in many types of applications including:

- Bookcases

- Cabinetry

- Decorative trim and accents

- Countertops

- Doors and door frames

- Set construction

- Shelving

- Flooring

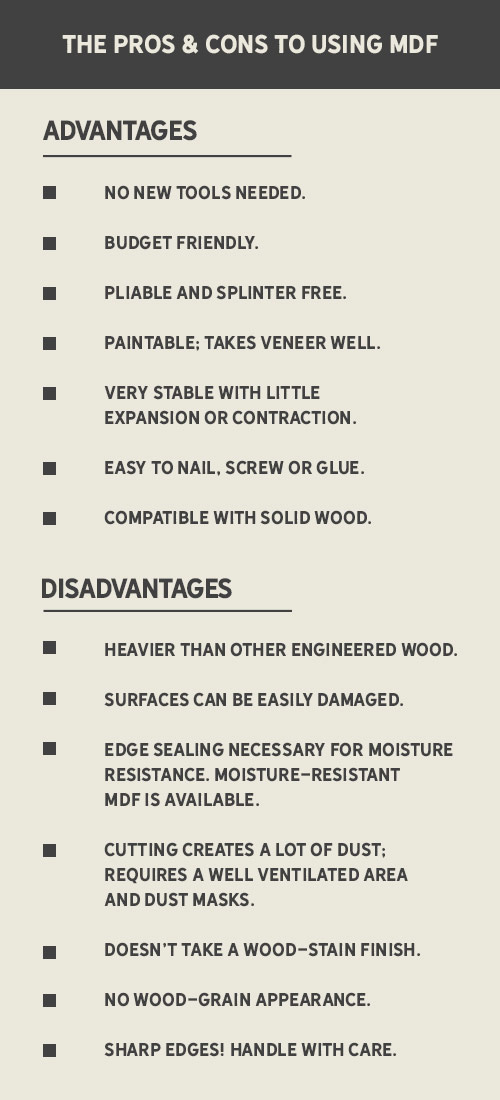

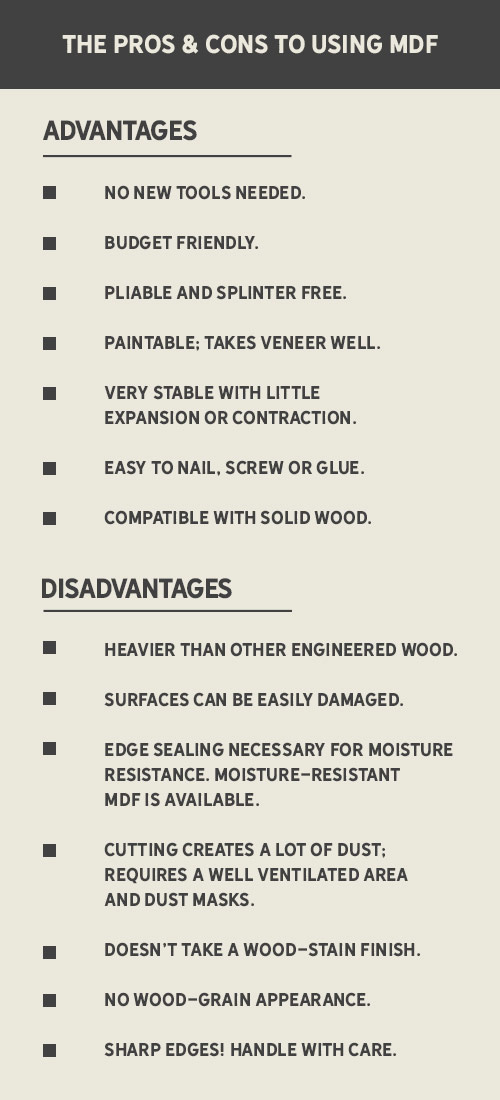

There are many pros and cons to using MDF, and you should weigh them all before making your final project materials choices.

Concerns About MDF Formaldehyde and Off-Gassing

One additional note about MDF is the potential for off-gassing of fumes from the materials. MDF is constructed with adhesives including some with urea-formadehyde (UF) which will dissipate into the surroundings for a time shortly after its manufacture (an average of about two years). Some state regulations require no added formaldehyde, so producers of MDF currently don’t include any. However, no forest product is completely formaldehyde free.

This risk of exposure and MDF’s tendency to create fine particulate dust are the reasons it’s extremely important to use proper respiratory and skin protection when working with MDF. In addition, well-ventilated (preferably outdoors) work environments and extensive clean-up after projects are complete can limit exposure to those working with MDF or residing in areas where MDF is installed.

Make Your Next Project Easier with MDF from McCoy's

No matter what your project, big or small, experts at McCoy’s can help you make the right choices to get your To Do’s crossed off your list. From raw materials to tools, McCoy’s can help you get started, get unstuck, or just get ‘er done.