Garage Upgrade: How to Epoxy a Garage Floor

Unsightly, stained garage floor? What even is that spill? Garage floor epoxy covers all of that plus gives concrete added protection for whatever you throw at it next. This is a great project for your next dedicated DIY weekend. The only hard part might be figuring out what to do with all the stuff that gets tossed into the garage. Maybe this is a good time to start a donation box, too.

What is Garage Floor Epoxy?

Epoxy creates a durable coating over your concrete garage floor by mixing a resin and a hardener together. It’s important to note that while the application process is similar, epoxy and paint have different properties and cannot be used interchangeably. There are a few different types of epoxies:

- Water-based. This type is common for household applications but may not be as durable as the other types. However, this is great for a residential garage.

- Solvent-based. While this type has a strong smell, it’s more durable than the water based.

- 100% epoxy. The strongest of the options should only be applied by professionals.

Garage floor epoxy typically comes in kits including the resin, hardener, color chips, and an etching solution. Of course, a newer garage floor is best for a smooth application. However, you can still apply the epoxy if your older (five+ years) floor is in good shape without any large cracks. The epoxy coat itself will last 10 to 20 years. You can even repair some small, cracked areas before application.

What You’ll Need

It’s possible you have almost everything you need already— maybe even in your garage!

- Broom

- Shop Vac

- Brush

- Bucket

- Garden Hose

- Gloves

- Eye Protection

- Mask

- Paint Brushes and Rollers

- Note: Use painter’s tape to remove any loose lint off the nap rollers.

- Painter's Tape

- Degreaser

- Epoxy Coating Kit

- Plastic Covers (optional)

- Spike shoes (optional)

Start with Prep Work

First things first, remove everything (boxes, bikes, lawnmower, etc.) out of the garage or at least off the floor. If you have hanging shelves, those items can stay but it’s best to cover them with plastic. Cars should stay out of the garage for the entire project and check the epoxy instructions for when the floor can be driven on after application.

Next, sweep the floor to remove any debris. After everything is out of your way, it’s time to assess the “porosity” of your concrete. That’s a fancy way of saying how much your existing concrete can absorb. Epoxy needs bare concrete and if you have any previous sealers, it won’t adhere well. You can test this by watering the floor with a garden hose and seeing where there is standing or beading water. Standing water could also mean grease spots from cars or other greasy projects.

If you have standing water, any existing grease should be removed by a biodegradable degreaser and scrubbed with a brush. Rinse with a garden hose. To remove any old sealers and to make the concrete ready for the epoxy, it’s important to etch. Some epoxy kits come with an acid etcher and the manufacturer’s instructions should be followed carefully along with wearing personal protection like gloves, eye protection, and a mask.

If you don’t have the acid or don’t want to use it as it’s a very strong chemical, a mechanical grinder can be used. Large concrete grinders can be rented for this project. Be sure to follow all manufacturer’s instructions. Clean up all dust from the grinding. The edges of the garage floor can be grinded with an angle grinder.

Any minor cracks should be repaired now using an epoxy crack filler. Lastly, use painter’s tape along the edges of your garage for clean epoxy lines and a smooth finish. Let everything dry.

Applying the Epoxy

Most residential garage epoxy coatings come with resin and hardener in two separate bags. This is because once mixed, the shelf life of the epoxy coat is only around two hours. You will need to know the square footage of your garage as the epoxy kits will tell you how many square feet each kit covers. So, after following the instructions to mix, it’s important to work efficiently. You can mix this in a bucket (we prefer yellow) with a stir stick thoroughly. The epoxy kit may have you let the mix rest for a period before use.

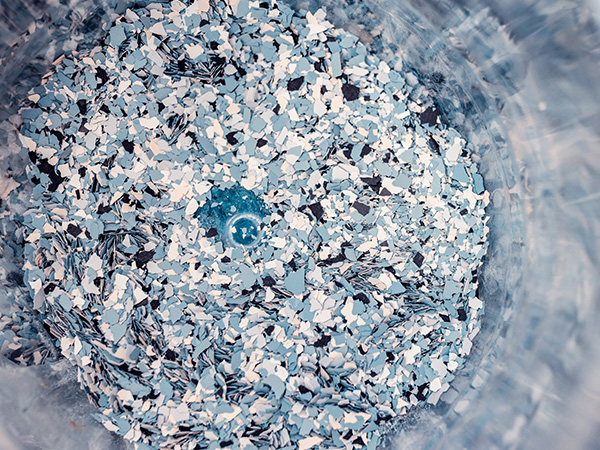

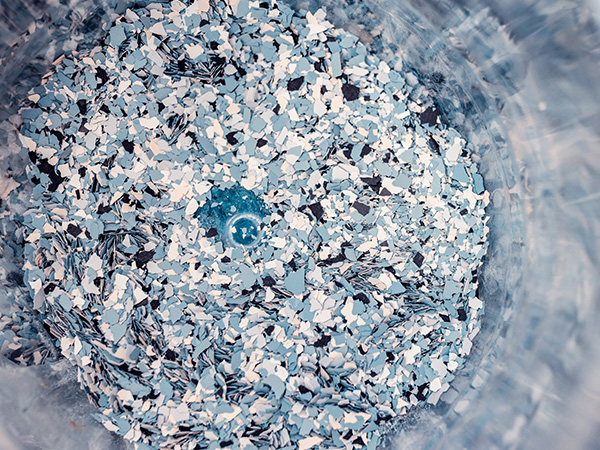

Note: If using color chips, don’t add them into the mix. That’s the fun part and it comes later!

Another Note: If you have a big enough garage that requires two or more kits to fully cover the garage, mix all the boxes’ resin and hardener together to avoid any color variance between boxes.

When the epoxy is ready, start applying it around the edges of the garage first. Then, gently pour the epoxy in small sections and roll out with a nap roller. Maintain a “wet edge” by rolling a new section slightly over the old one. Work in sections around two feet by six feet. Just like any paint job, a second coat allows for even coverage and extra protection. Wait 12 hours or overnight before adding the second coat using the same steps as above.

We promised the fun part. After the second coat and while it’s still wet, fling the color chips onto your floor. These are supposed to fall like rain down onto the wet epoxy. It’s best to fling them from eye level instead of your waist for a more even application. If you have spiked shoes made for this type of project, you can walk on the wet epoxy to distribute the color chips. If not, you can apply the chips to the wet areas as you work on the second coat.

Make sure you follow the instructions of the kit as to when you can put your stuff back and drive on to the floor.

Give Your Garage an Upgrade at McCoy’s

Garage floor epoxy can transform your space from an oily, dirty mess to a garage every weekend DIY can be proud of. Ready to get started? Buy online and pickup your items on your way home from work or have them delivered for free! Need storage and a whole new organization system for when you have to put everything back in the garage? We have that, too.