How to Prevent and Fix Warped Wood

When you’re ready to tackle a project using raw lumber, the last thing you want is to discover you have warped wood. Wood warp can happen at many different stages during the lifespan of a piece of lumber. McCoy's takes preventative measures in our lumberyards to help prevent wood warp and there are lots of ways you can help prevent warp once you get your wood home. However, if you end up with bent lumber in your project pile, you can fix a warped board and set it straight again.

What is Wood Warp?

A piece of wood can warp, or become misshapen, if it loses moisture at different rates from one area or another. This unbalanced drying means that the wood in the drier area shrinks and pulls against the wetter areas, leading to a bowing or warping in the lumber. Wood can warp early or late in its lifespan, and warping can occur while being stored at a lumber yard, store aisle, or even your home woodshop or garage.

Types of Warping

One warp is not the same as another. There are five primary types of warped wood:

- Bow: Bowed wood is raised at both ends, similar to a bow and arrow.

- Twist or Wind: A twisted piece of wood might remind you of a twisted ribbon or pretzel stick. The warped ends curve in opposite directions.

- Kink: Kinked wood is raised on one end, like a straight arm with the wrist tilted. It can occur due to a knot in the wood.

- Crook: A crooked piece of wood bends because of shrinkage along one side.

- Cup: Cupped wood has raised edges that each turn towards the center of the piece of wood, creating a shape similar to a vessel.

Why Wood Warps

All wood shrinks as it dries, but wood can warp if something in that drying process is uneven. Wood that is wide-grained or from the outer layers of a tree (which are inherently younger than the tree’s inner or heart wood) is more prone to warping. Also more prone to warp is wood that is stored in a more humid environment with little air circulation, such as a humid garage in the heat of summer. Hardwoods with fine grains, and those from tropical environments (where trees have more natural oils), tend to warp less easily than softwoods, which can have wide grains. In addition, thicker cuts of wood will take longer to expand or contract due to moisture absorption or loss, making them less prone to warping.

4 Ways to Prevent Wood Warping

Wood can warp at many different stages of its life cycle. Freshly harvested wood can be manufactured into straight, flat boards, but arrive warped at their next destination. Straight boards can become warped if stored improperly at a lumber yard, or in a home woodshop. An important factor in preventing wood warping is to monitor conditions in which wood is kept before it is used.

- Store wood in an area with adequate ventilation. Many lumber yards are outdoors, but if the boards themselves sit in tall piles for weeks, months, or years, they won’t get any airflow on the interior portions of the boards.

- Store wood away from impacts from rain, snow, and other wet environments. Lumber left outside without adequate cover will be more likely to warp as its wet fibers dry. Wood can naturally absorb and release moisture indefinitely, so just because a piece of wood is old doesn’t mean it’s impervious to the possibility of warping.

- Bundle or group boards to prevent warp. To prevent warping such as cupping, stacks of boards should be stored neatly together, with lengthwise pressure - especially when it comes to wide or long sheets of lumber.

- Monitor humidity. Simple hydrometers can save you from guessing at your humidity levels, especially in areas outside the home, like a garage or storage space. Watch for rising humidity during summer or wetter weather and increase ventilation with fans or use dehumidifiers to help remedy environments that could lead to wood warp.

How to Tell if You Have Warped Wood

It’s relatively simple to spot warped wood, either in a piece from your wood pile or before you purchase a piece of lumber. You can take the individual piece of wood, lay it on a flat surface, and inspect the edges for signs that they do not lie flat. Wood warp can also be seen if you use a level across a piece of wood and look for points where the lumber does not meet the level’s straight edges.

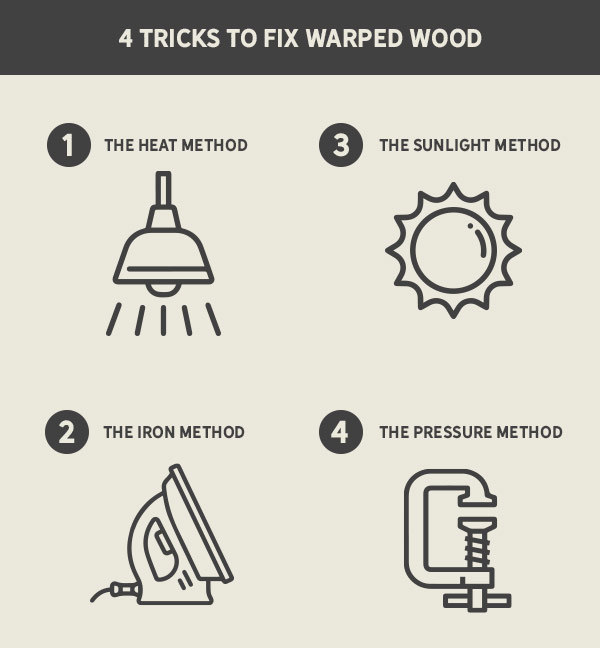

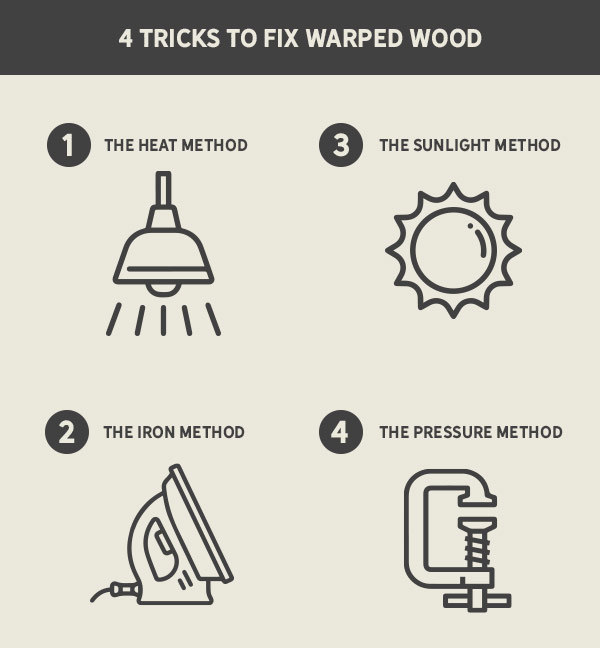

4 Tricks to Fix Warped Wood

Even if you have wood at home and discover it’s warped, you don’t have to get rid of that lumber right away. There are several ways you can attempt to remedy warped wood:

- The Heat Method: While heat (applied to wet conditions) can cause wood to warp, it can also be the solution to the problem. You can apply a heat source such as a heat lamp to a clamped piece of warped wood until the bend is remedied. You want to be careful not to damage the wood during this process, however. Care should be taken to avoid igniting any wood while applying heat.

- The Iron Method: A household iron may be able to apply heat and pressure in a simple way that can un-warp a piece of wood, especially if it’s thin. A board wrapped in wet towels across its entire surface can be “ironed” on the device’s highest setting. Be careful to protect your skin to avoid burns, especially when checking the wet towels and board. They will become extremely hot! Repeat this method as needed to achieve the desired results.

- The Sunlight Method: Sunlight and exposure to the elements could have warped your wood pile, but it also could help you fix it. Wood wrapped in moist (not dripping wet) towels, especially large sheets that have curved, can be affected by lots of direct sunlight. Place the wood with the warp facing downwards, cover with the wet towel, and give it time in direct sunlight for the heat and moisture to help the fibers expand in the board. It could take several days to fix the warp.

- The Pressure Method: Damp paper towels should be used with this method, along with several clamps to keep a warped piece of wood straight against a flat surface. This can be effective especially on wood that has the flexibility to bend but is warped in its natural state. Clamp the wood to a stable surface, cover it with damp paper towels, and wait for the fibers to relax and bring the wood to a straight and stable position. The warmer the conditions, the better. You may need to wait several days, or weeks.

McCoy's Lumber Yard: We Handle Wood the Right Way

At McCoy’s we know that each piece of lumber you take home is important. That’s why we take the best care of every piece of it in our lumber yard. From protecting lumber in the yard from exposure to rain and the elements under our big awnings and allowing for adequate ventilation, to helping you make final inspection of every piece we load into your vehicle, we want you to be 100% satisfied that your lumber is perfect. If you ever have questions on wood warping, lumber storage, or any step of your project, our lumberyard crew be happy to answer them.

Reviewed by Brandon Bishop

McCoy's In-House Expert